- Home

-

Products

-

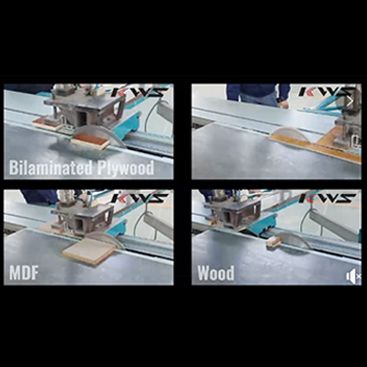

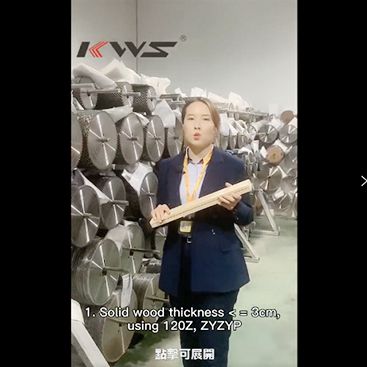

Saw Blade for Cutting Wood

Saw Blade for Cutting Wood

-

Cold Saw for Cutting Steel

Cold Saw for Cutting Steel

-

Saw Blade for Cutting Aluminum

Saw Blade for Cutting Aluminum

-

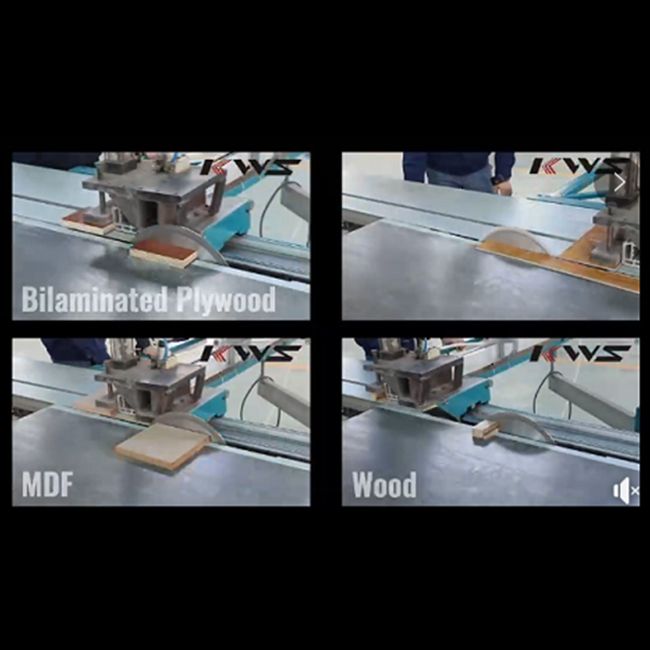

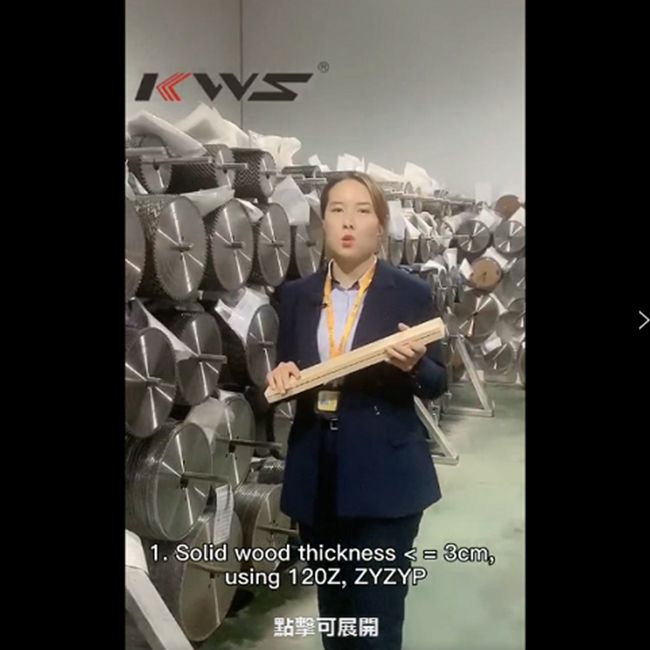

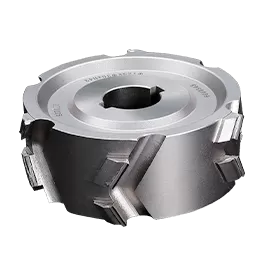

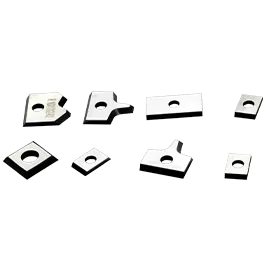

PCD Pre-milling Cutter

PCD Pre-milling Cutter

-

Drill Bit

Drill Bit

-

Router Bit

Router Bit

-

Profile Cutter

Profile Cutter

-

Planer Knives

Planer Knives

-

Collet Chuck Holder

Collet Chuck Holder

-

Grinding Wheel

Grinding Wheel

-

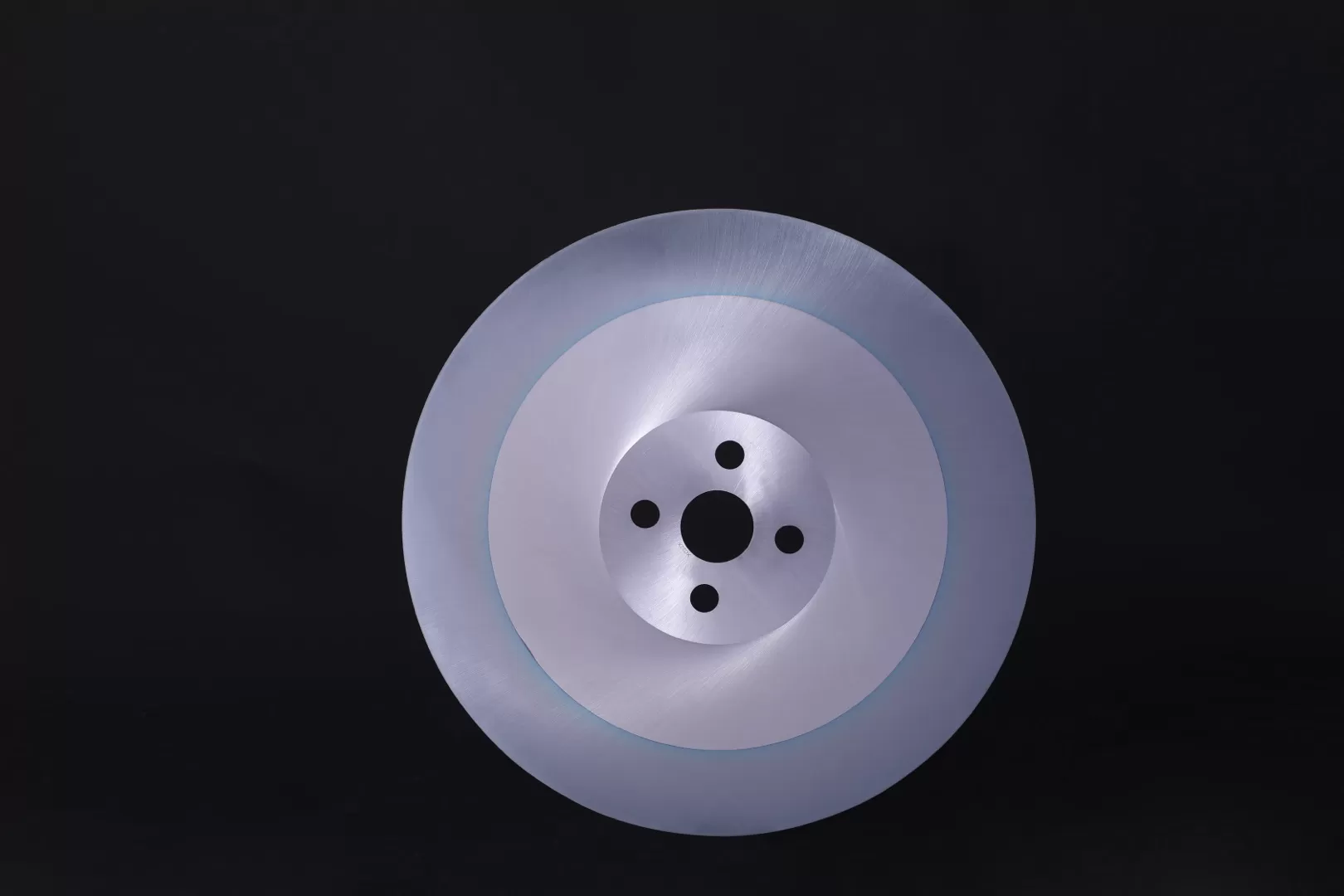

HSS Saw Blade

HSS Saw Blade

-

Chop Saw

Chop Saw

- Universal Saw Blade

- Saw Blade for Edge Banding

- Panel Sizing Saw Blade

- Adjustable Scoring Saw Blade

- Conical Scoring Saw Blade

- Multiripping Saw Blade with Rakers

- Grooving Saw Blade

- Saw Blade for Single Chip

- Thin-kerf Cutting Saw Blade

- Cold Saw for Medium and Low Carbon Steel Cutting

- Cold Saw for High Carbon Steel Cutting

- Cold Saw for Pipes Cutting

- Cold Saw for Stainless Steel Cutting

- Cold Saw for Manual Device

- TCT Saw for Aluminum Cutting

- Salde Drill Bit

- Suqare Hole Drill Bit

- Mortising Cutter

- Dowel Drill

- Super Duty Dowel Drill Bit

- Hinge Drill Bit

- Step Drill Bit

- Milling Cutter for Aluminum

- Through Hold Drill Bit

- Engraving Bit

- Mortise Bit

- Panel Cutter

- Finger Joint Cutter

- 1/4 Corner Round Cutter

- Half Round Cutter

- Grooving Cutter

- Door Frame Cutter

- Door Plank Cutter

- Edge Banding Cutter

- Tenon Cutter

- Helical Cutter Block

- Adjustable Grooving Cutter

- Cabinet Door Cutter

- Planer Cutter with Replacable Blade

-

- About us

- Download

- Join Us

- Contact Us